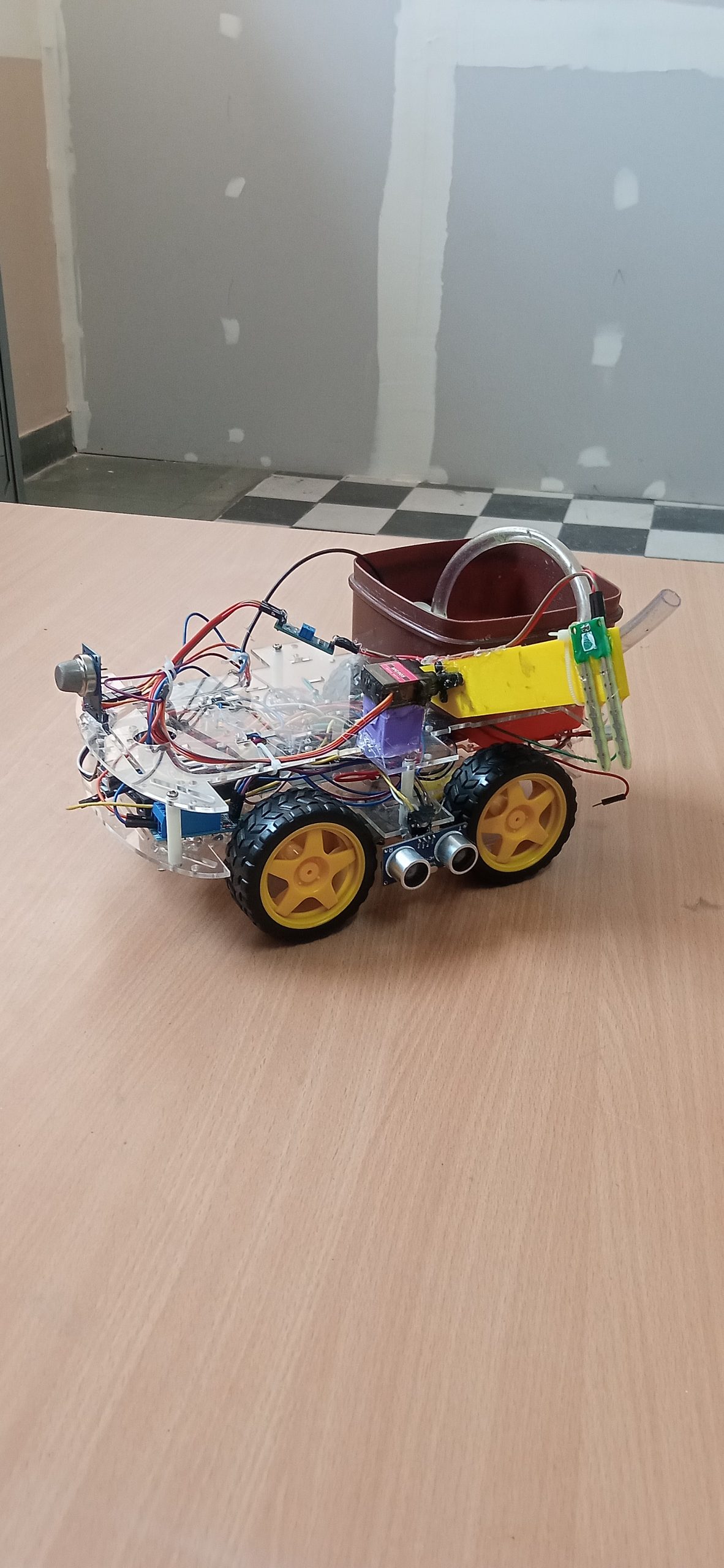

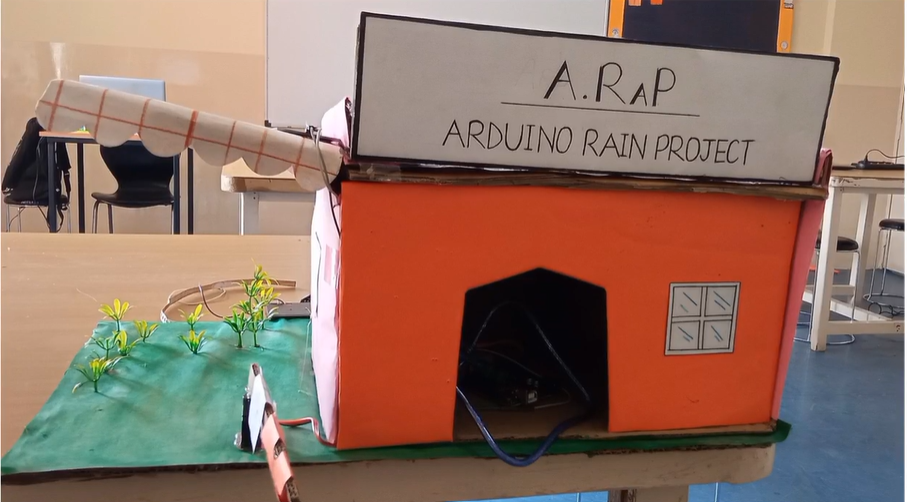

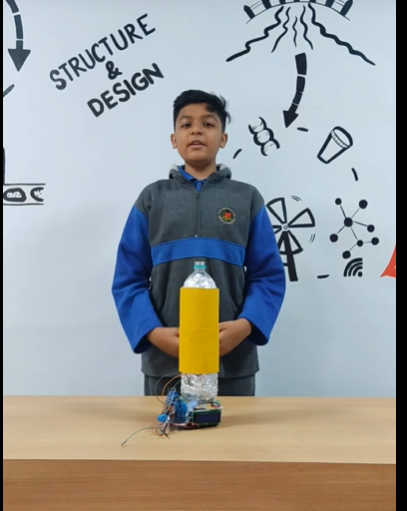

In our modern world, managing waste effectively is a growing challenge. Non-biodegradable waste, such as plastics and metals, poses significant environmental threats, leading to pollution and overflowing landfills. Traditional waste sorting methods are labor-intensive and often inefficient, resulting in poor recycling rates and increased environmental harm. There is a pressing need for innovative solutions to automate and improve waste segregation processes, thereby enhancing recycling efficiency and reducing ecological footprints. Non Biodegradable Waste Separator project offers a smart and efficient solution for waste management. By automating the separation of non-biodegradable materials, it significantly improves recycling rates, reduces manual labor, and minimizes environmental pollution. This innovative approach promotes sustainability, helping to create a cleaner, greener future for our communities.

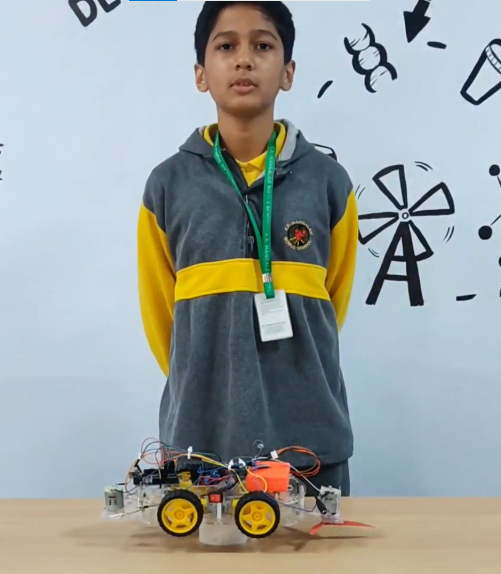

Required Components:

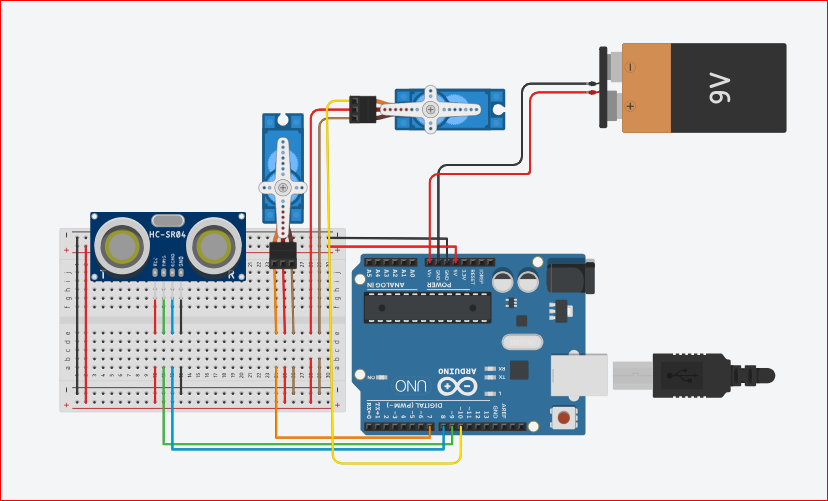

- Arduino UNO x1

- Servo Motors (x2)

- Ultrasonic Sensor x1

- DC Motor x1

- 9V Battery x1

- Breadboard x1

- Connecting Wires

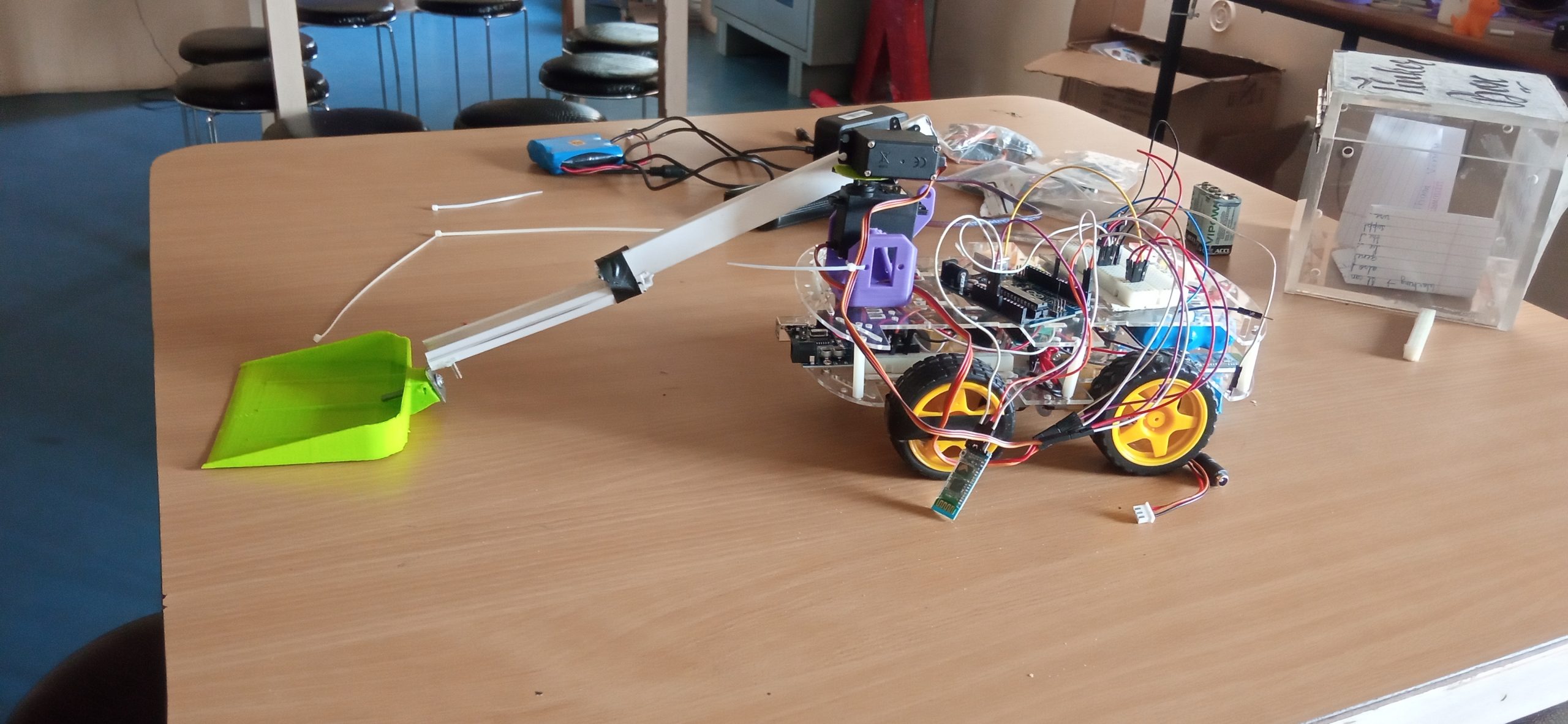

Components and their functions:

- Arduino UNO: The Arduino UNO is a microcontroller board that act as the brain of the waste separator, controlling sensors and motors based on programmed instructions.

- Servo Motors : These motors are used to position sorting mechanisms or flaps accurately, directing waste into the correct bins based on sensor inputs.

- Ultrasonic Sensor: This sensor detects the presence and distance of waste items, triggering sorting actions when waste is identified.

- DC Motor: This motor drives the shaft attached with the DC motor or rotating mechanism that moves waste items towards the sorting area.

- 9V Battery: This battery provides the necessary power supply for the Arduino and connected components, ensuring the system operates independently.

- Breadboard: A breadboard is used for prototyping and connecting all electronic components without soldering, making it easy to modify the circuit.

- Connecting Wires: These wires connect various components to the Arduino and breadboard, enabling communication and power distribution throughout the system.

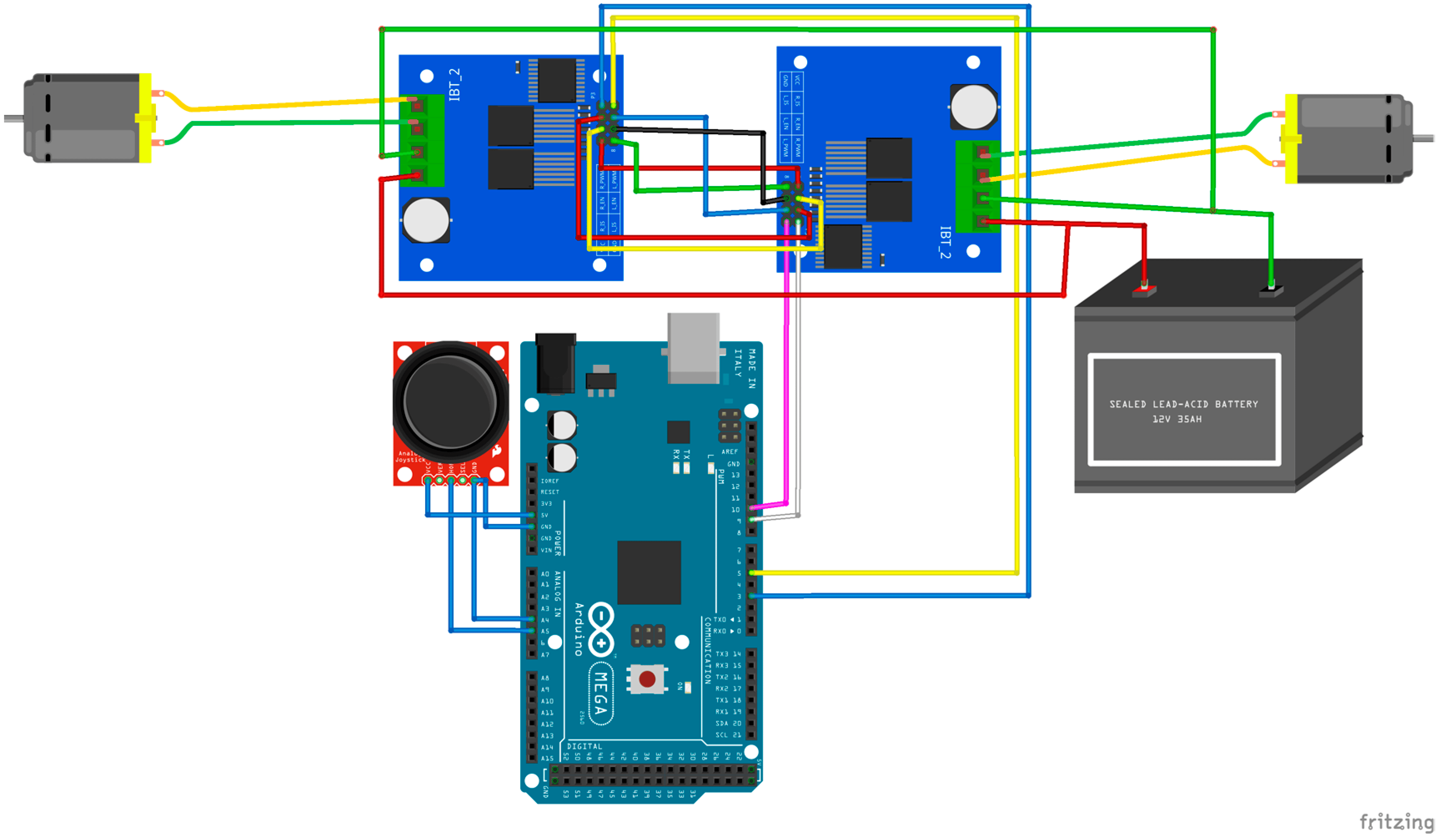

Steps to Assemble the Circuit

Connect the Servos:

- Attach the signal wire of the first servo motor to pin 7 on the Arduino.

- Attach the signal wire of the second servo motor to pin 10 on the Arduino.

- Connect the power and ground wires of both servo motors to the 5V and GND pins on the Breadboard.

Connect the Ultrasonic Sensor:

- Connect the Trig pin of the ultrasonic sensor to pin 9 on the Arduino.

- Connect the Echo pin of the ultrasonic sensor to pin 8 on the Arduino.

- Connect the VCC pin of the ultrasonic sensor to the positive rails of the breadboard.

- Connect the GND pin of the ultrasonic sensor to the positive rails of the breadboard.

Power the Arduino:

- Connect the 9V battery to the Arduino using a battery connector.

- Attach the positive wire of the battery connector to the Vin pin on the Arduino.

- Attach the negative wire of the battery connector to a GND pin on the Arduino.

Breadboard:

- Connect the 5V pin from the Arduino to the positive rail of the breadboard.

- Connect a GND pin from the Arduino to the negative rail of the breadboard.

- Distribute power and ground connections to the servo motors and ultrasonic sensor from the breadboard rails.

#include <Servo.h>

Servo myservo1; // Existing servo motor

Servo myservo2; // New servo motor

const int trigPin = 9;

const int echoPin = 8;

long tmeduration;

int distance;

void setup() {

myservo1.attach(7); // Attach the first servo to pin 7

myservo2.attach(10); // Attach the second servo to pin 10

pinMode(trigPin, OUTPUT);

pinMode(echoPin, INPUT);

Serial.begin(9600);

}

void loop() {

// Send ultrasonic pulse

digitalWrite(trigPin, LOW);

delayMicroseconds(2);

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

// Measure the duration of the echo pulse

tmeduration = pulseIn(echoPin, HIGH);

// Calculate distance

distance = (0.034 * tmeduration) / 2;

// Control the first servo based on distance

if (distance <= 200) {

myservo1.write(90);

} else {

myservo1.write(0);

}

// Control the second servo based on distance

// Here, I'm using the same logic as the first servo.

// Modify this according to your specific requirements.

if (distance <= 200) {

myservo2.write(90);

} else {

myservo2.write(0);

}

// Print the distance for debugging

Serial.print("Distance: ");

Serial.println(distance);

// Wait for a short period before next measurement

delay(500);

}